Wire cleaners and wire rope greasers are essential in the world of cable repair, in which precision is crucial. These advanced devices are vital to ensure that cables function smoothly and last for longer in many industries. In this article, we delves into the role of lubricating and lubricating wire ropes as well as wire cleaners in cable maintenance by analyzing their uses as well as the benefits and profound impact they play on the overall efficiency of operations.

Understanding how wire rope lubricants work

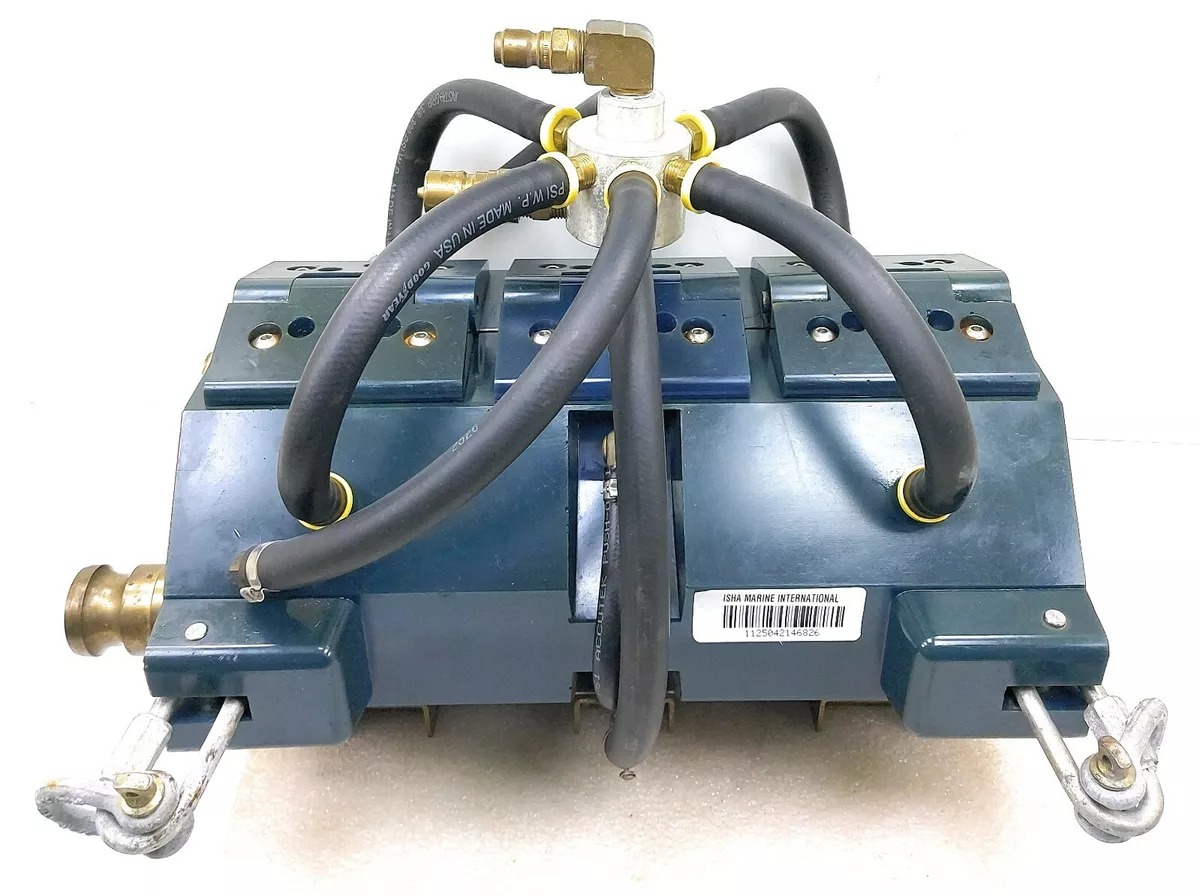

Wire rope lubricators are also known as wire rope lubricators are specialized devices that apply an oil-based lubrication system to ropes in a systematic manner. This process is vital for preventing rust, reducing friction and enhancing the overall endurance. The lubricator distributes lubricant equally across the length and widening of the wire rope, to ensure that it is completely protected from wear.

The role of wire cleaners in Cable Maintenance:

Cleaners for wires (also referred to as cable cleaners) are crucial in keeping the cleanliness and hygiene of cables. They are developed to remove dirt, fluids and other contaminants that can build up on the cables during various processes. Wire cleaners are vital when working in harsh environments where cables are exposed to harsh conditions. They will ensure the best performance and prevent potential damage. Click here Wire Rope Lubricator

Optimizing Cable Lifespan:

Wire lubricators as well as wire cleaners utilized together can dramatically increase the life of cables. By applying lubrication in a systematic manner using wire rope lubricators and removing pollutants with wire cleaners cables are protected from the detrimental effects of friction, corrosion, and external elements. This ensures the integrity of the cable and leads to increased efficiency and decreased maintenance expenses.

Efficiency in Application:

Wire rope oilers are created for easy use and effectiveness when used. They can be utilized on different sizes and types of wire ropes. They are able to be used in a variety of ways in cable maintenance practices. The lubrication process is automated and applied in a coordinated way, which ensures consistency and eliminating the risk of uneven coverage.

Ability to Adapt in a Changing Environment:

The adaptability of the cleaning and lubrication of wire ropes are vital in businesses that expose cables to harsh conditions. This is the case for drilling, construction or maritime operations. These tools are built to withstand extreme conditions and provide high-quality cable maintenance tools in a variety of conditions.

Cost-effective maintenance solutions for your home:

Implementing a proactive approach to maintenance of cables through the use of lubricators for wire ropes and wire cleaning products proves to be a cost-effective option in the long run. These tools of the future are an affordable investment when as compared to the expense of repairs, replacements and downtime which could be caused by neglecting maintenance.

Conclusion:

Wire cleaners and lubricators for cable ropes are the guardians who ensure cable integrity and precision across a wide range of industries. Removal of pollutants and the application of lubricants contributes to the longevity and preservation of cables. This reduces maintenance and enhances the efficiency of operations. In an industry that is dependent on cables to carry out critical processes, using the latest tools for maintaining cables such as wire rope lubricators and wire cleaners is not just a wise choice, it’s an absolute necessity.